Lots of little things lately, but nothing exciting enough to take pictures of and share.

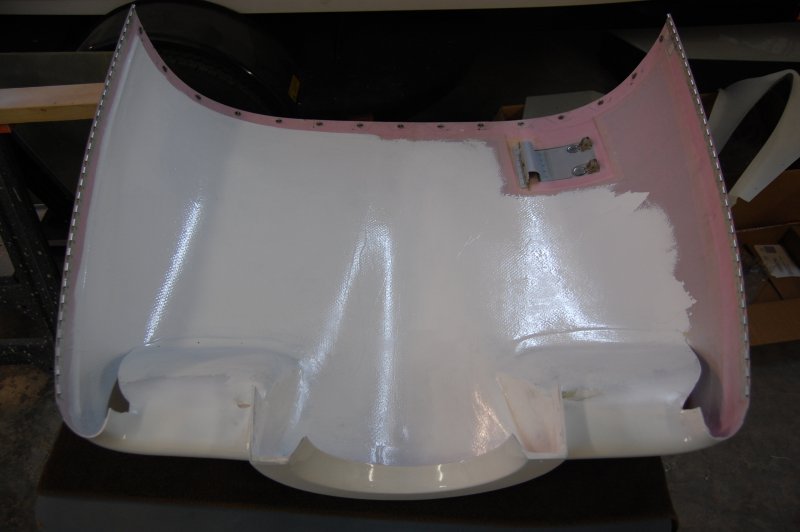

Here's something, I've been trying to decide what to paint the inside of the cowl with. I wanted something I could brush on that would seal the cowl from oil and and or gas. I started thinking about the engine compartment in an inboard boat. So I went to the marine store and sure enough they had "BilgeKote". Made for fiberglass and is fuel and oil proof. Perfect!

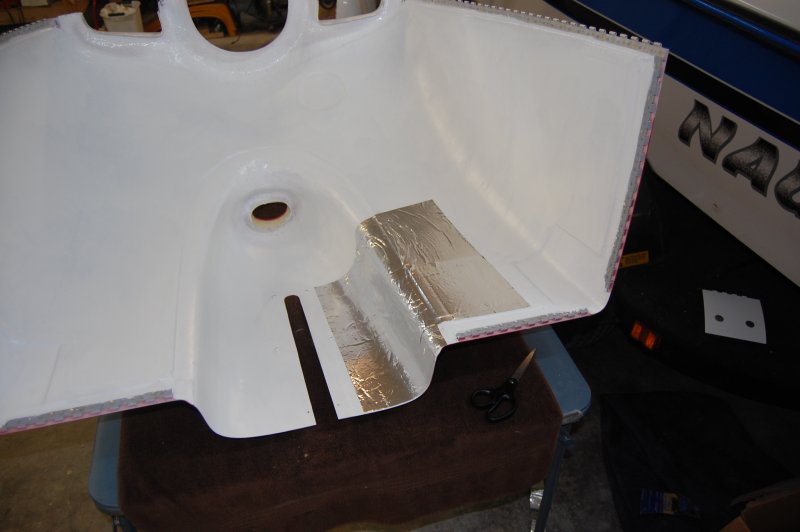

Squeegied 3 layers of resin on the spinner to fill the pinholes

And primed

Heat tape for the exaust area

Friday 2/11/11 The Big Move!!!

Up early as usual I tried to get everything together before everybody showed up 8:30am.

This is where the plane has sitting for awhile but it needs to spin around and go forward out the other door.

Here it is turned 90 degrees

And finally all the way around

Most of what I want to take today

Lane got up and came out to see what was going on. He later decided to stay home from school to be part of this big event.

We figured it would be easier to load the plane downhill then up so we put the trailer in front of the house.

After moving the right wing around a couple times, we decided to only take one wing this trip. Not quite enough room for the other.

Here we go!

We made it!

Lane's hangar bike.

She's home! Thanks a ton to Greg, Scott, and Dave for helping me move it! Also to Ross for letting me borrow his truck!

Dave, the guy I bought the hangar from, gave Lane his electric mini bike. He loves it!

Sunday morning, back at home, I started putting the wingtip lights together.

Then headed up to the hangar. Ross, Kerry, and the kids swung by to check out the hangar. Lee from work also came by.

Lots of people flying today. Glad I didn't build the whole plane here because I'd have never gotten anything done.

Dan Tracy in his RV-7 was my first fly in visitor.

Got my spinner painted. I did all the prep but had a shop in Tacoma shoot it. I didn't want to set up another booth and all that.

Hauled up the other wing in the back of my truck and Trinna and I put them on. Haven't installed the final "close tolerance" bolts yet, but will as soon as I get a chance to go over everything one last time.

Hung the rudder

Worked on the landing lights

18 degrees when I left the house this morning at 4:10. Leaving the hangar at 6:20 it wasn't much warmer. Thank God for a heated and insulated hangar!!

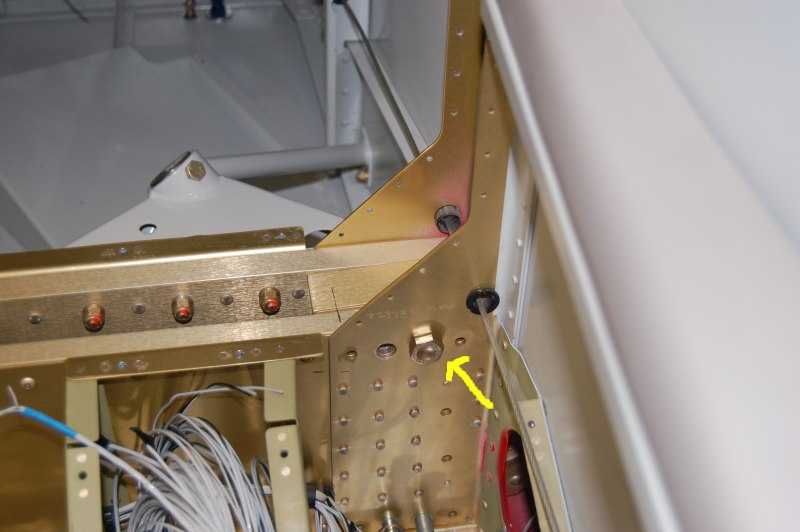

Here are the close tolerance spar bolts for the passenger side.

Vans recommends using LPS2 on the bolts.

First bolt in, not too bad.

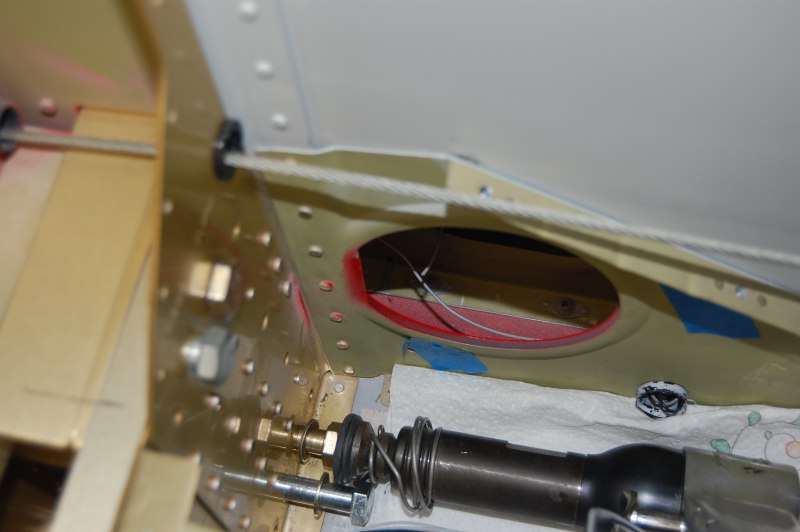

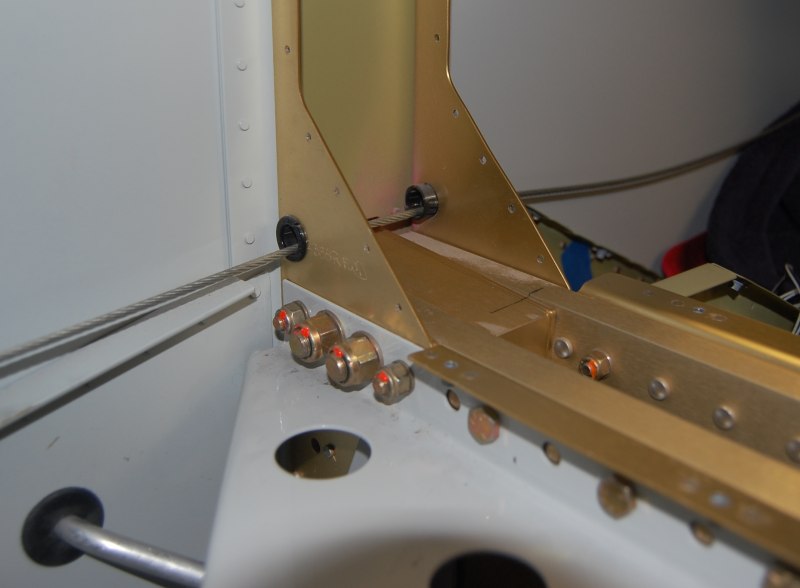

There isn't enough room to tap in the bottom bolts with a mallot, so a rivet gun is used.

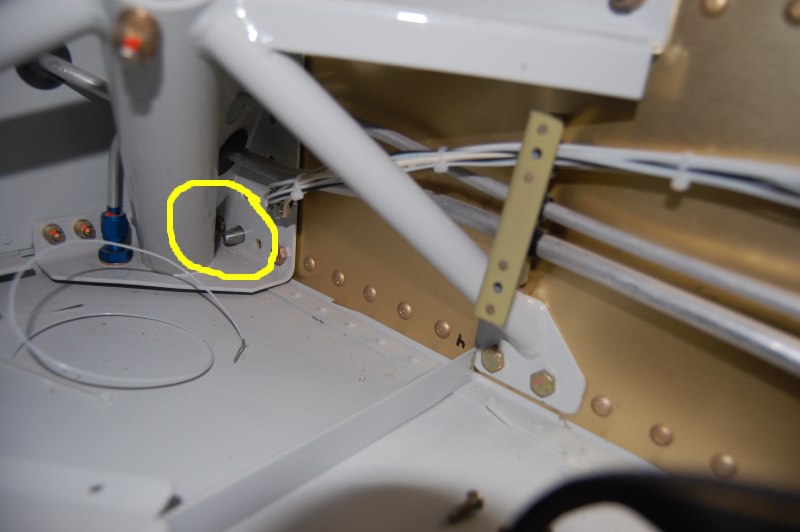

You have to put the nut on the bottom bolts as soon as they come out of the hole. Here you can see the drift pin still installed.

There they all are. 2 hours and 40 minutes to do this side. The bottom nuts are very tough to get on.

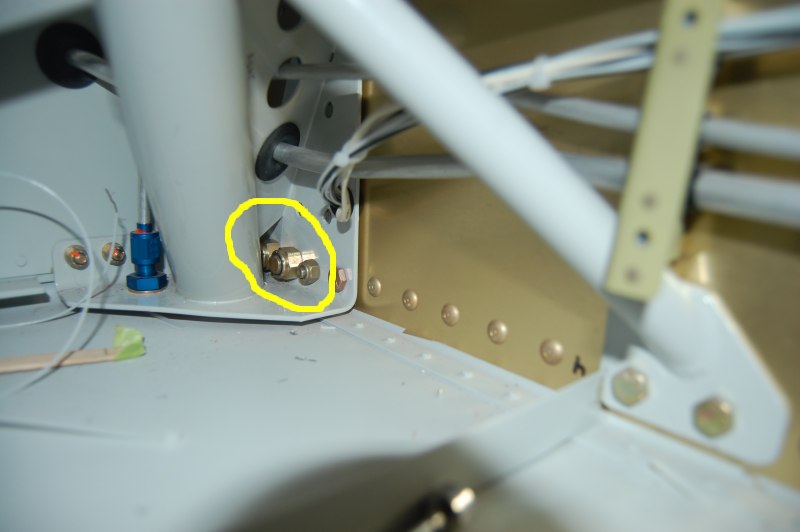

The bottom nuts, one you can't see.

The other side done.

Back