Drilling the passenger stick. Since it is removable, it comes in two pieces.

Here it is all put together

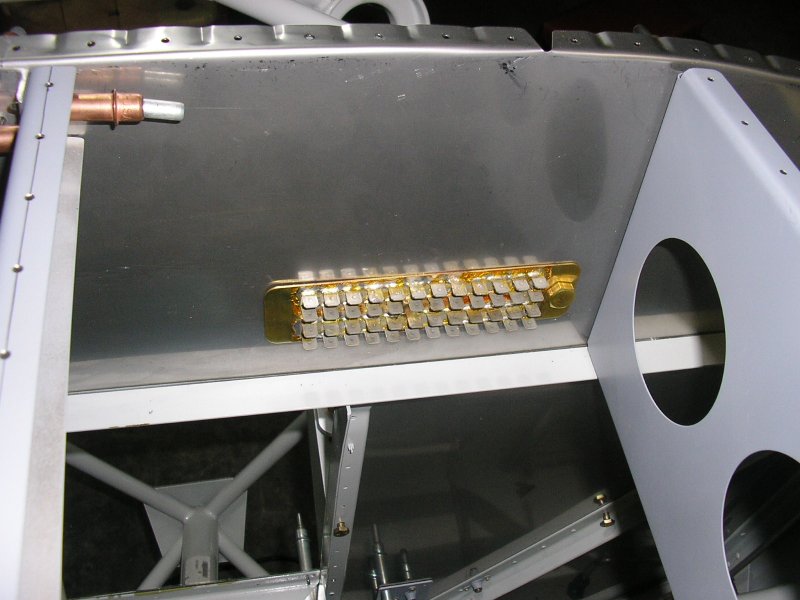

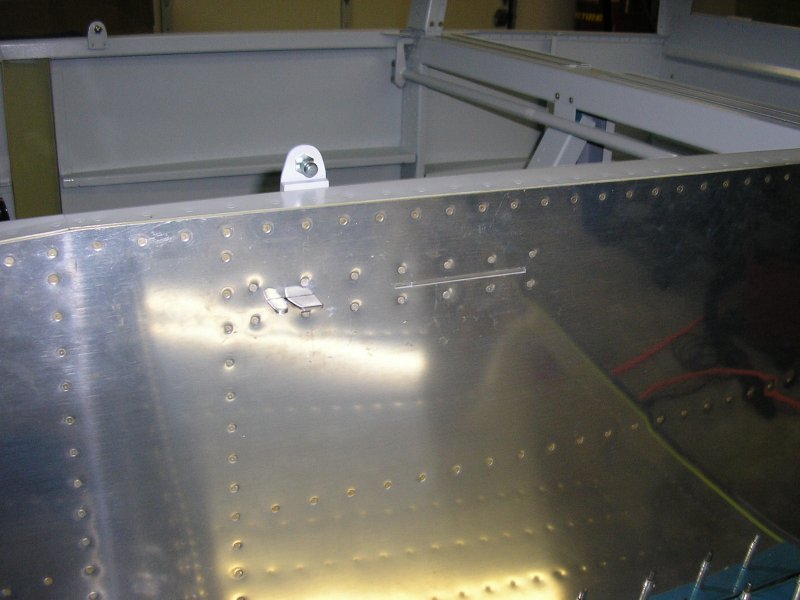

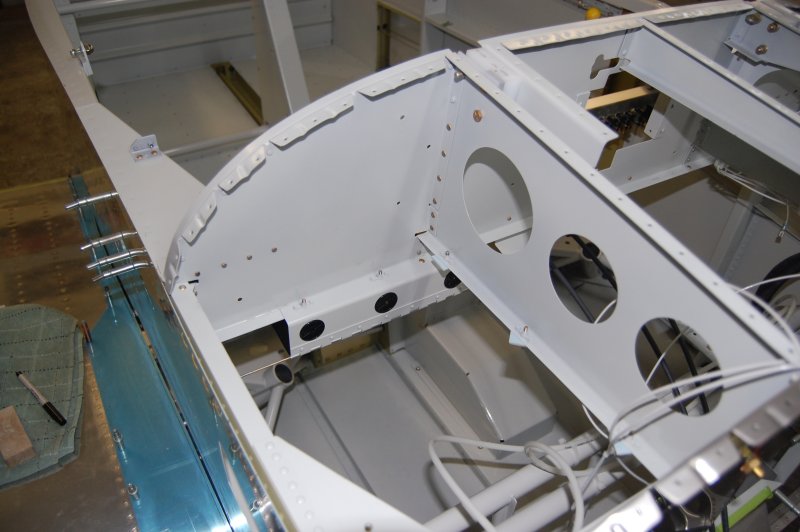

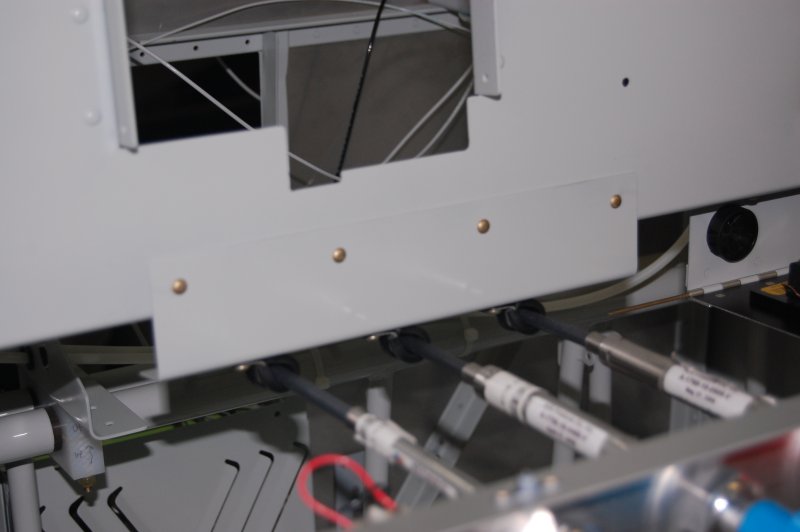

Possible fuse block locations

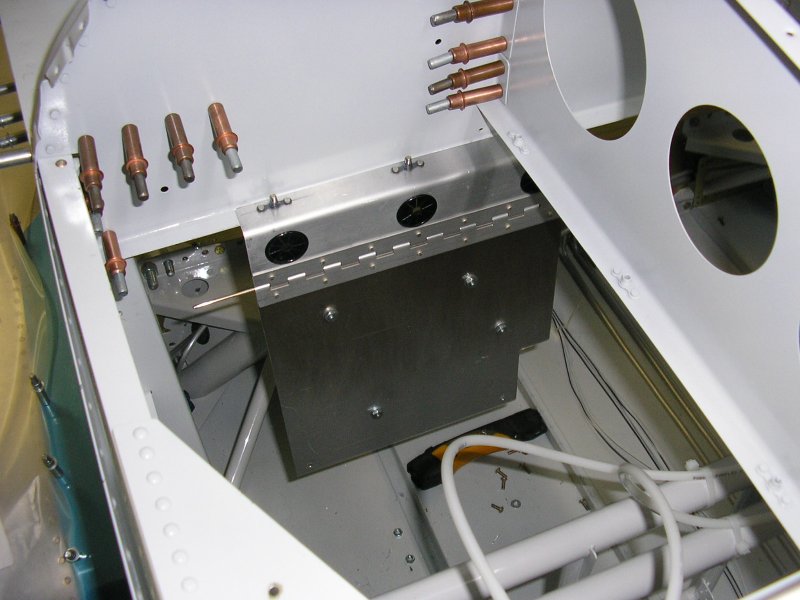

Grounding buss mounted on aft side of firewall

Towards the center of the picture you can see the brass bolts of the grounding buss sticking through.

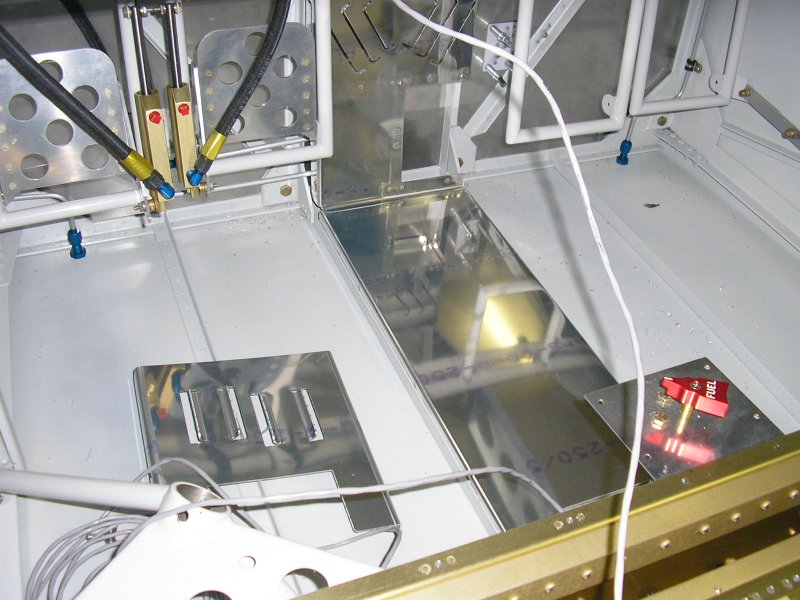

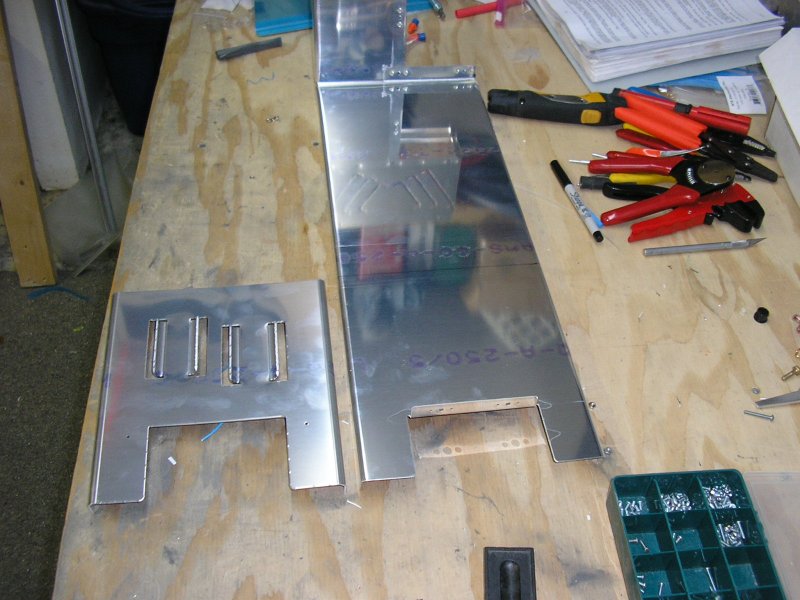

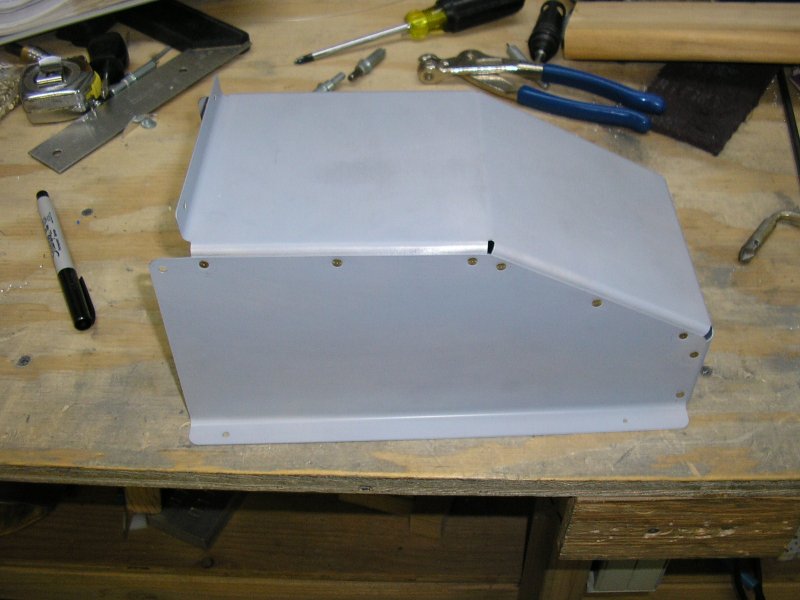

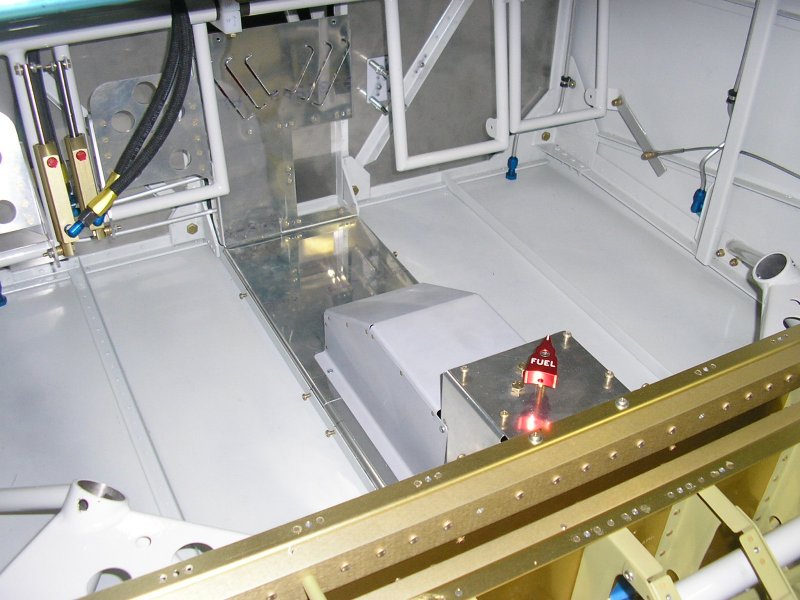

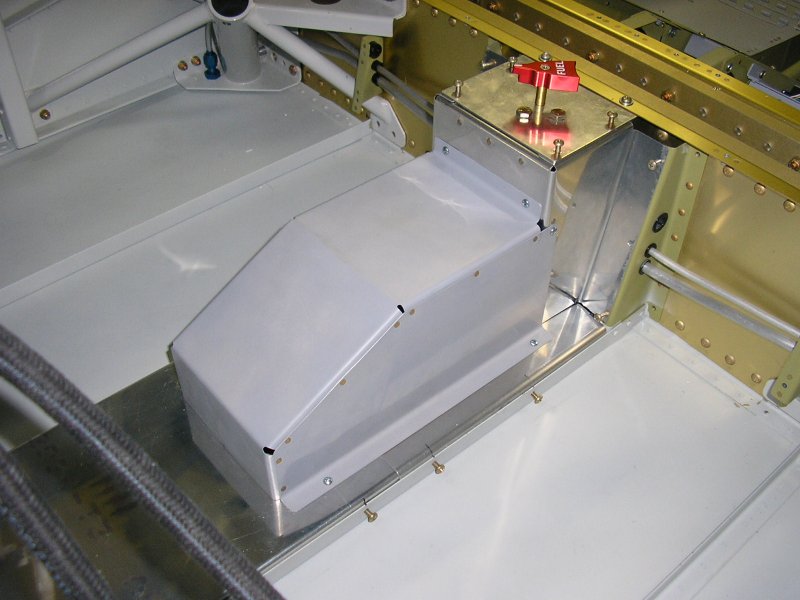

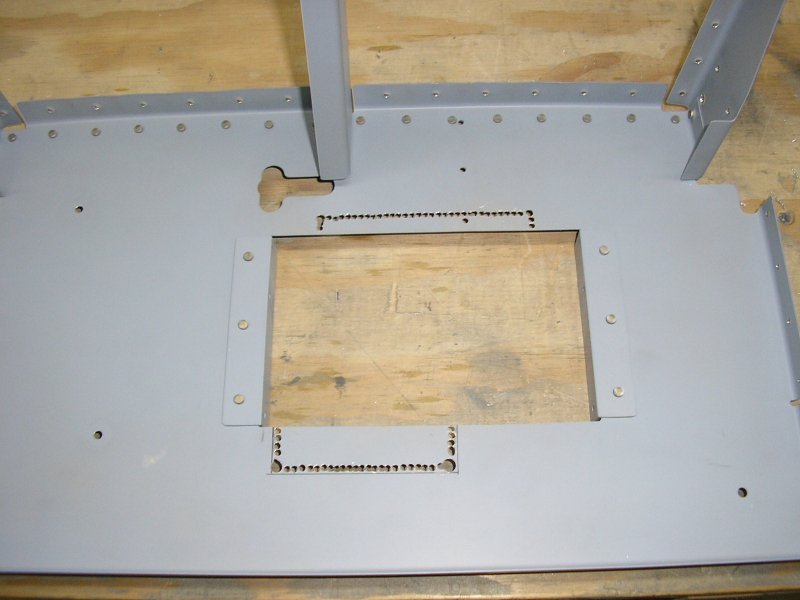

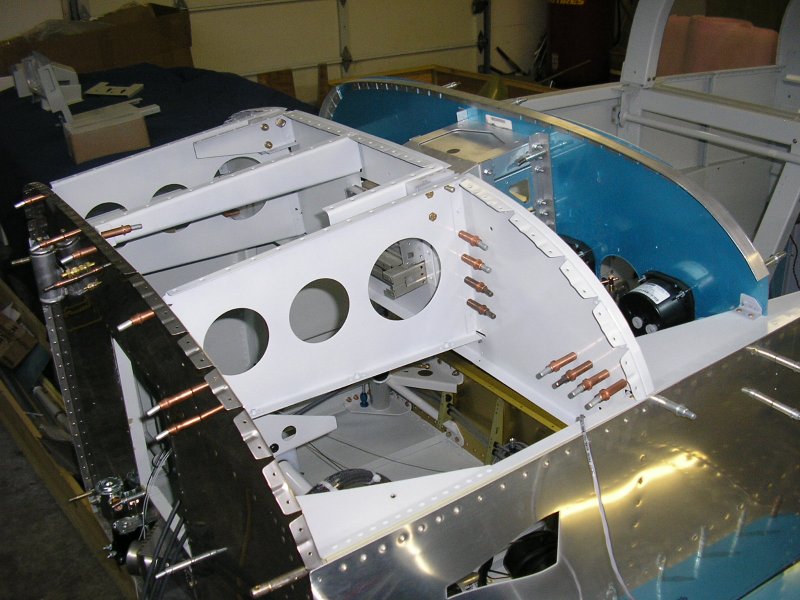

This is the console / electric fuel pump cover / heat diffuser.

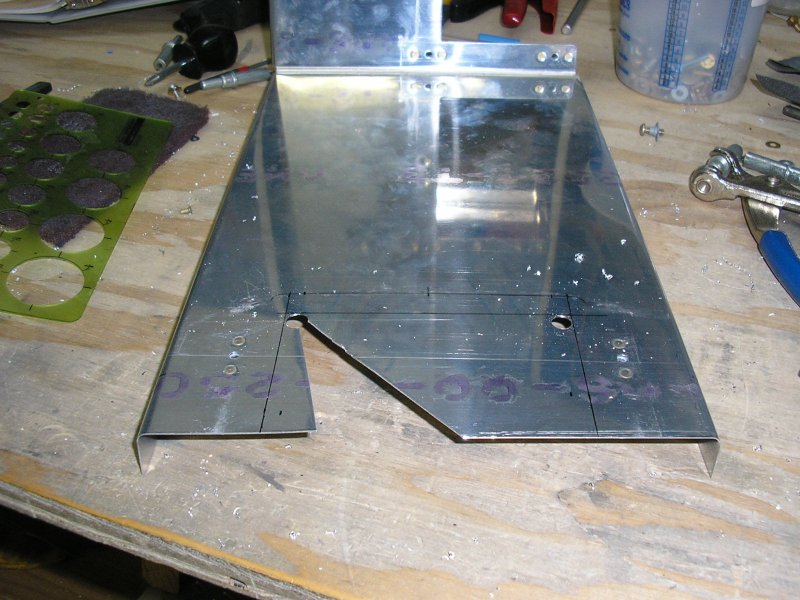

First you have to pretty much cut it in half because it is made for a carburated plane, but I'm going fuel injected. The piece on the left goes in place of the chopped off piece and provides a mounting location for the fuel pump and filter.

This cover also has to be modified to clear the electric fuel pump.

Lots of nutplates

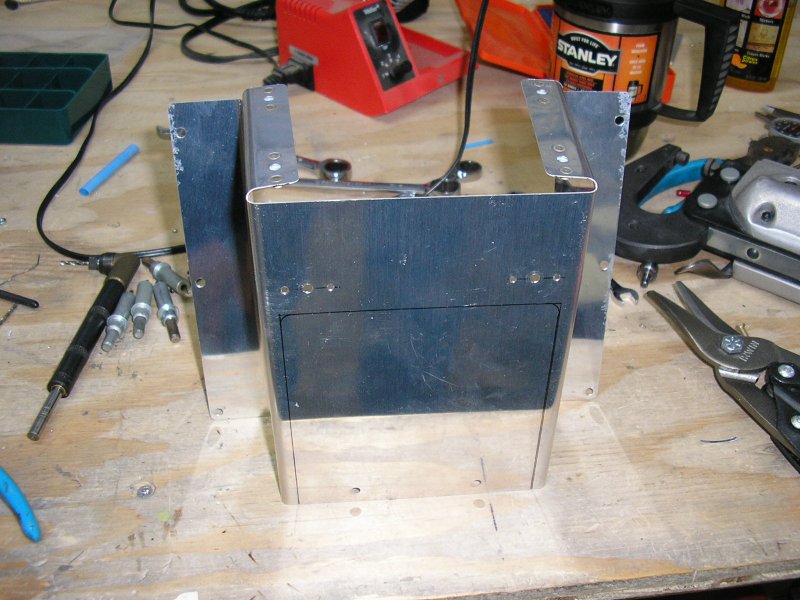

Riveting the electric fuel pump cover.

The last modification is made to make room for the fuel line tubing. This is the first couple of cuts with the tin snips. The whole square will be cut out.

Here it is all put together

This is the top front skin getting dimpled. This may not seem like a big deal, but this is the last skin on the plane!

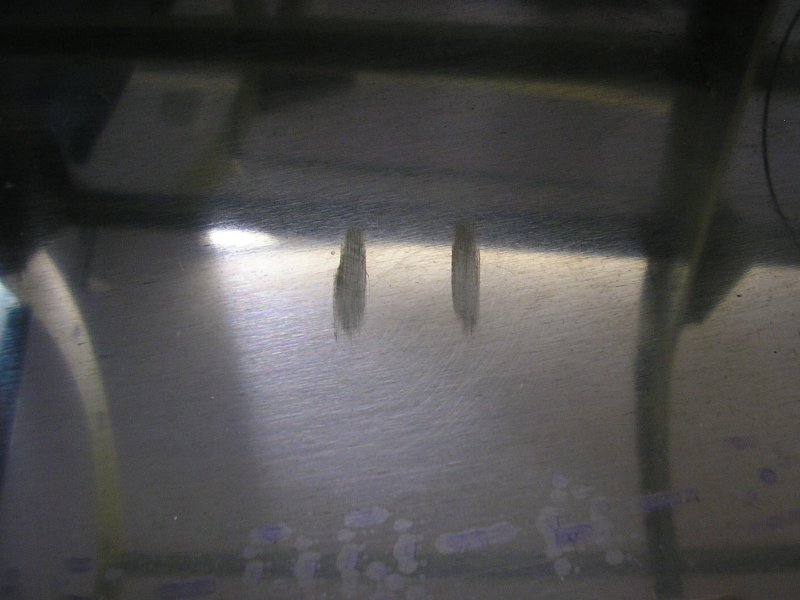

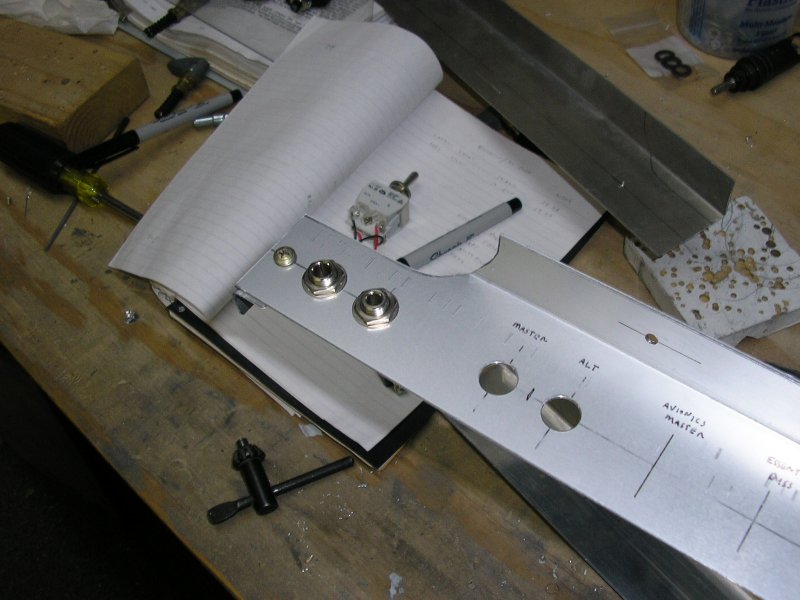

I decided that although the top "Audio Panel" and bottom "Transponder" in my radio stack do not penatrate the subpanel, their wiring probably should. Since it would be too difficult to cut these with a jigsaw, I elected to use the hole method.

Just large enough to pass the connectors though and plenty big for all the wiring. These edges will be cleaned up and lined with grommet material.

A side view to see what the heck I'm talking about

I used my forming tool to bend the heat diffuser louvers.

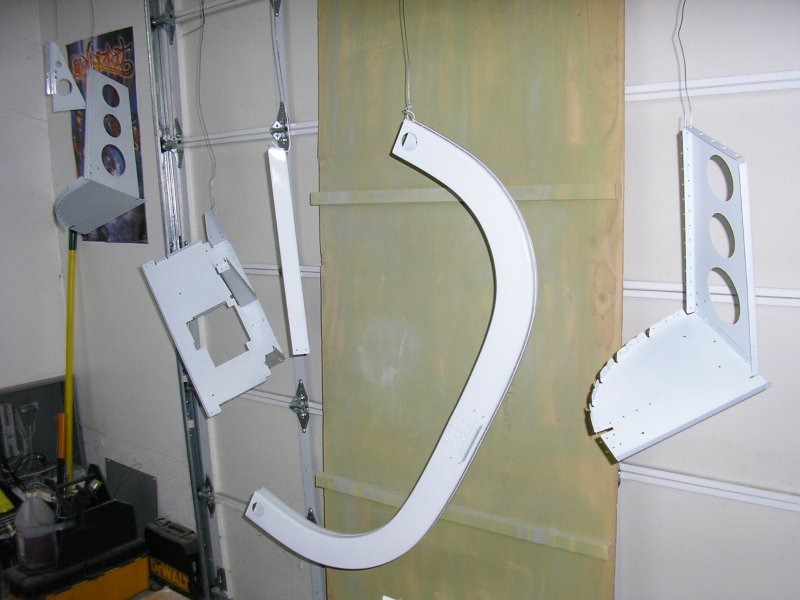

More painting

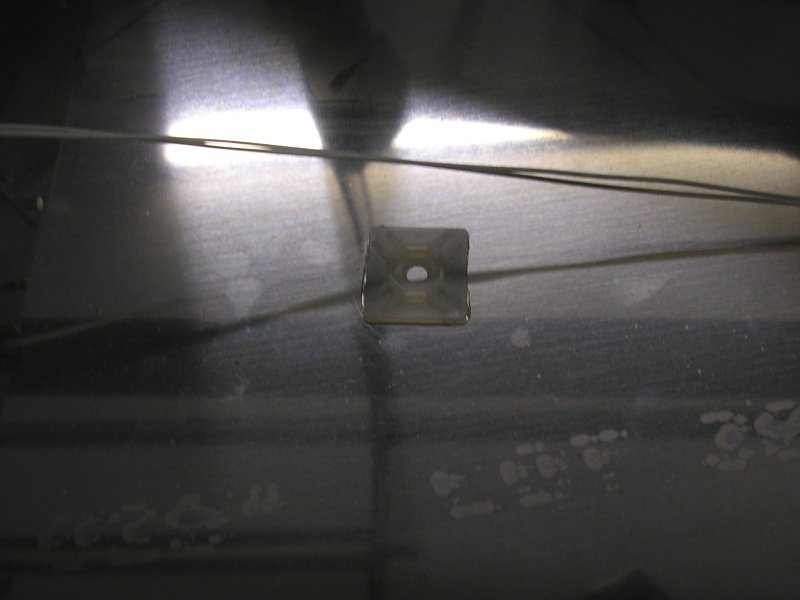

Since most sticky back tiewrap bases eventually fall off I've decided, like others, to glue them down. First you have to soak them in acetone to get the sticky off.

I cut slots in this thin cardboard so I could rough up the aluminum where the glue will be.

Here it is all glued down. I don't think they're going anywhere.

Here is the elevator trim wiring on the new bases. (Getting dusty back there)

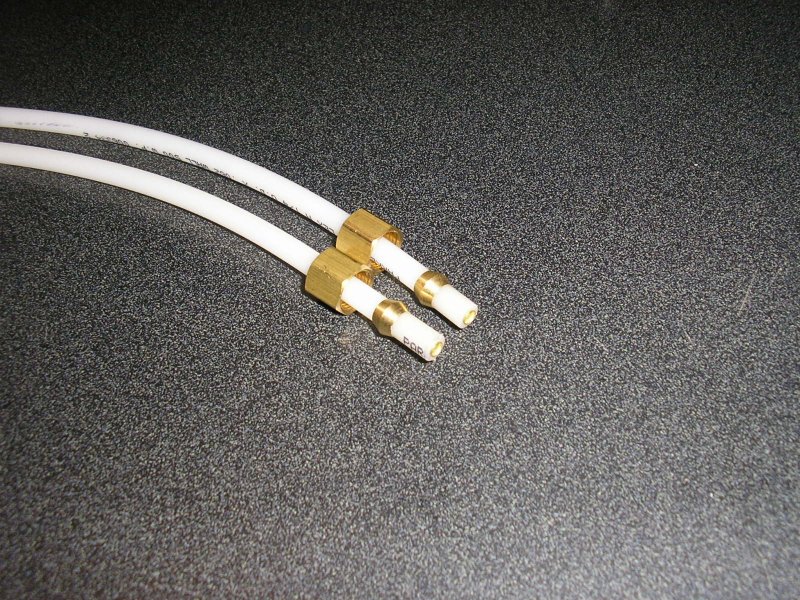

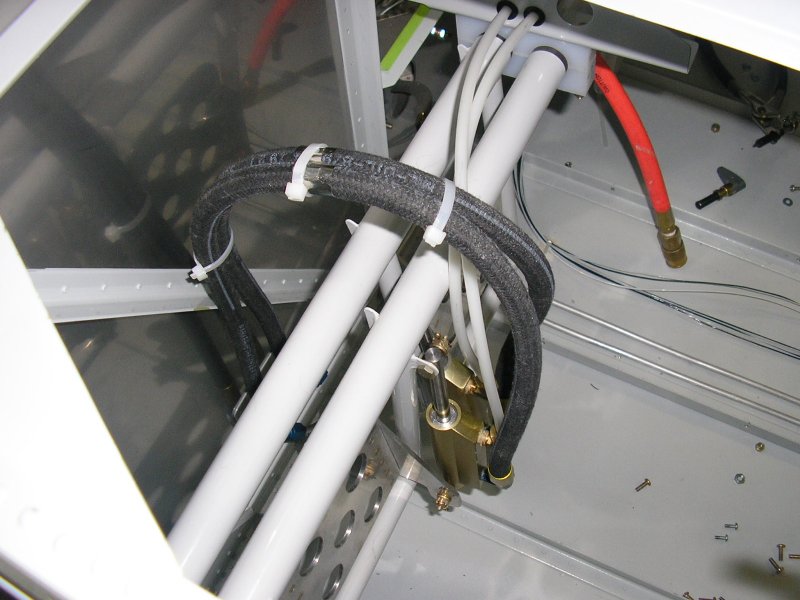

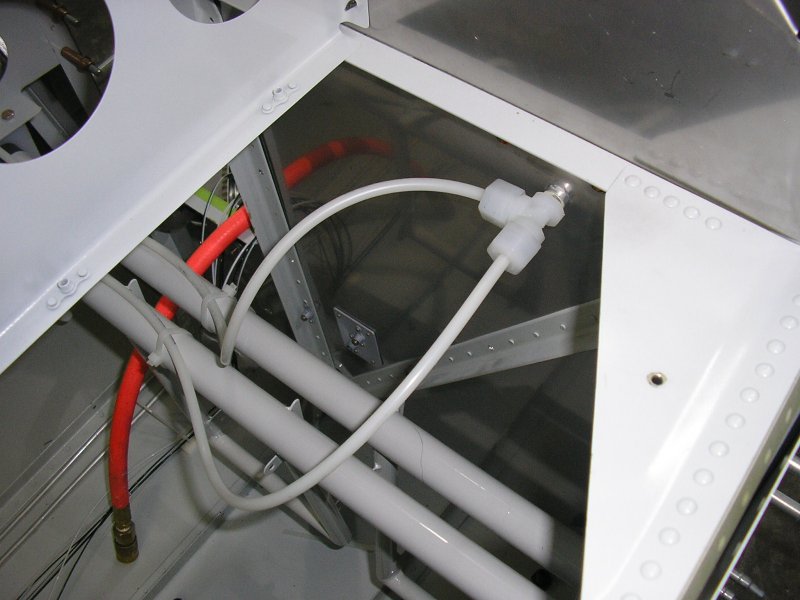

This is the plastic tubing that runs form the brake resevoir down to each brake cylinder. Since it is so "stiff" Van's recommends boiling the ends so you can slide in the inserts.

Riveted the canopy latch.

11/16/08 Broke 2000 hours today! What a project!

Back